Oden Mapping Data

Oden Multibeam and Chirp Sonar System

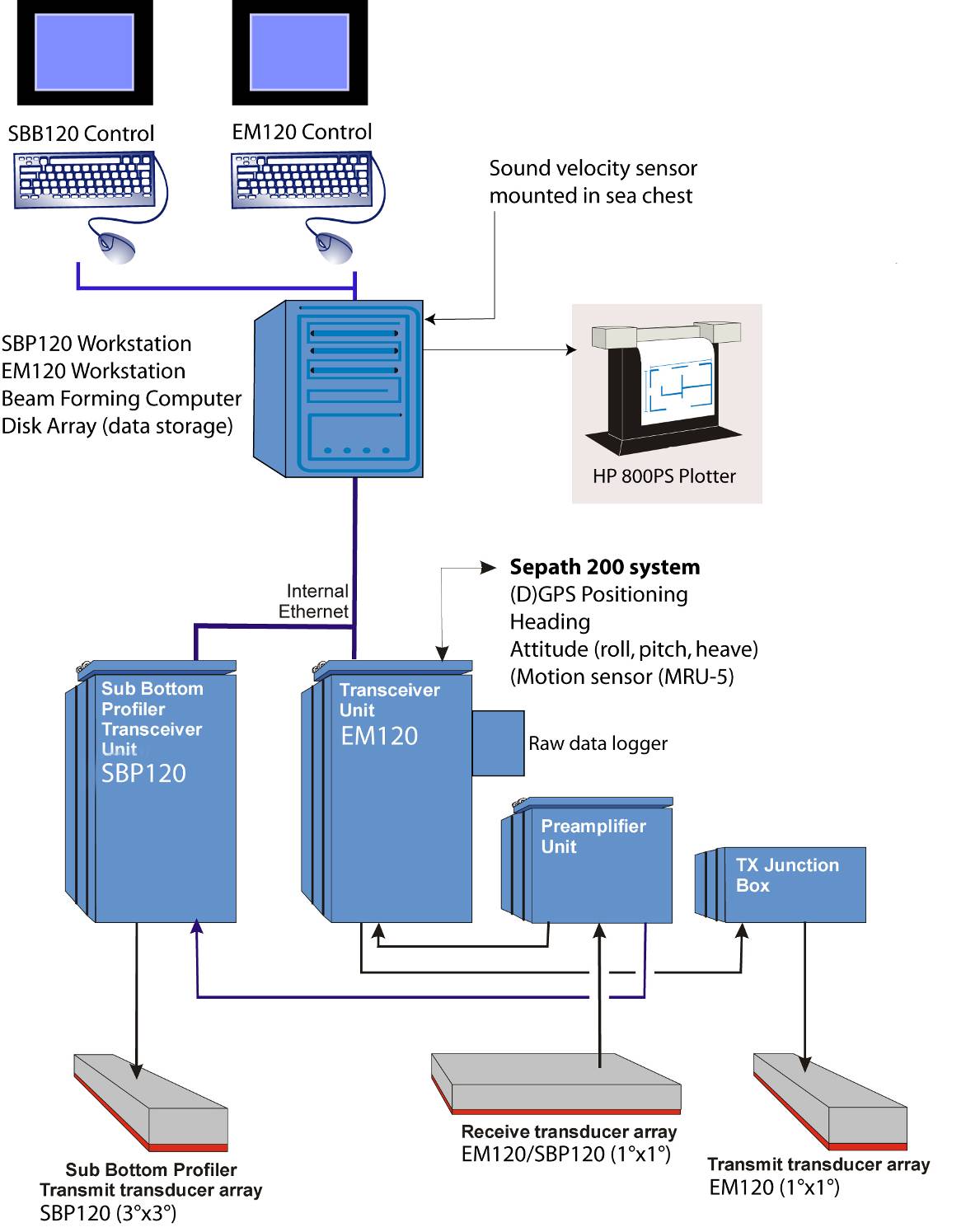

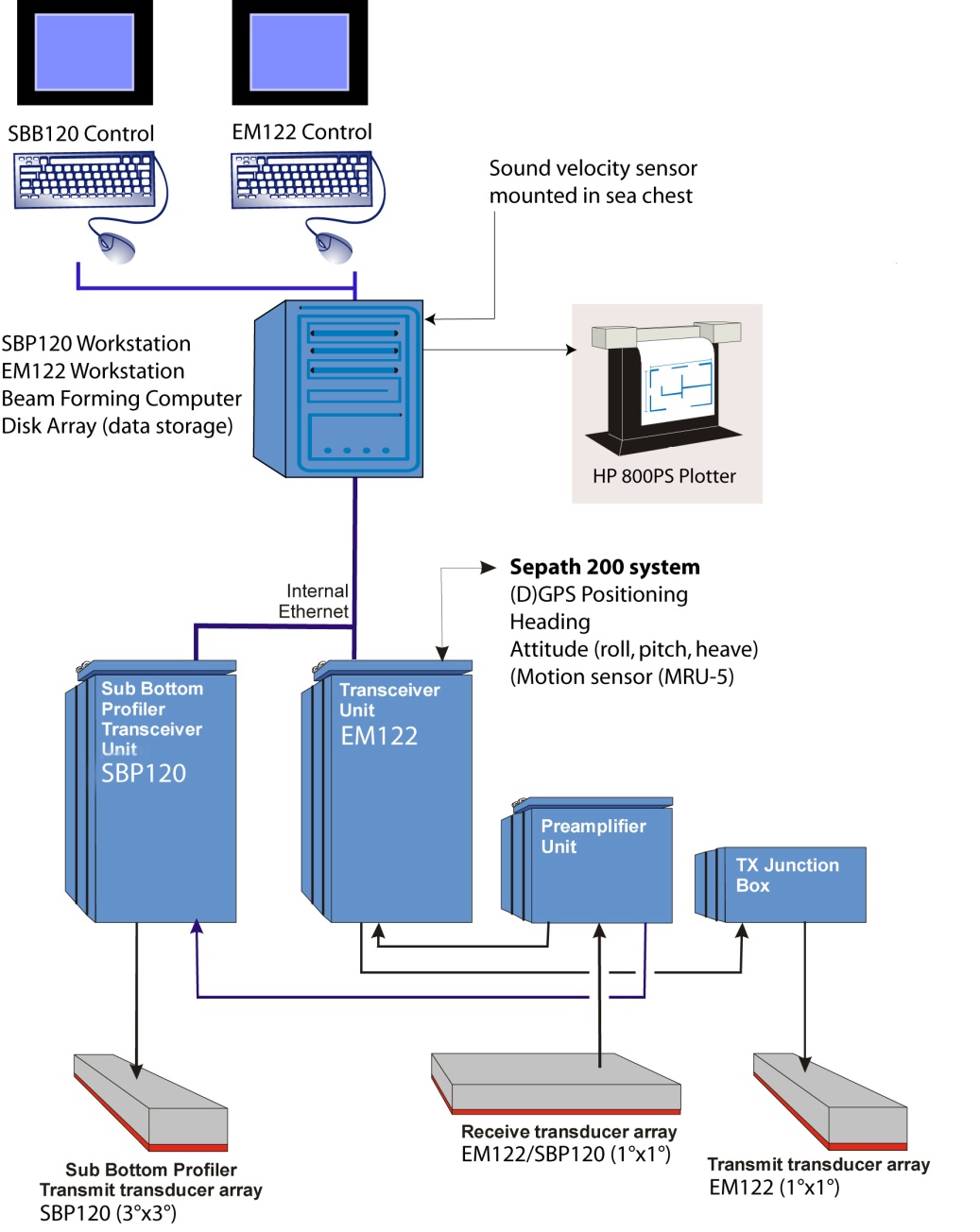

Oden was equipped with a multibeam echo sounder and chirp sonar profiler in 2007. Knut and Alice Wallenberg Foundation (KAW) and Swedish Research Council (VR) financed the system and the installation was financed by the Swedish Maritime Administration. A Kongsberg EM120 (1°x1°) multibeam echo sounder with the integrated subbottom profiler SBP120 (3°x3°) was installed 2007 while Oden was placed in dry-dock between April 17 and May 15 at Öresundsvarvet in Landskrona. Table 1 lists the main technical specifications of the installed EM120 and SBP120 as well as the specifications of the EM122, which replaced the EM120 in 2008. Following the spring of 2008 all data have been acquired with the EM122 system. Figure 1a and b show schematic illustrations of the Oden multibeam components for the EM120 and EM122 configurations respectively. Multibeam systems require precise information of the sound velocity in the water column for depth calibration. Therefore, a Conductivity Temperature Depth (CTD) probe from Sea-Bird Electronics (Model SBE 9 plus) was included in the multibeam system setup on Oden. In addition, sound velocity is directly measured regularly using probe mounted in Oden's sea water chest located just aft of the multibeam receive transducer array. The transducer arrays mounted in the hull of Oden (see photos below) are protected from ice impact by plates made of polyurethane plastic reinforced by imbedded titanium rods. The polyurethane later proved to have been hardened in insufficient conditions resulting in delaminating between the plastic and the titanium. These windows were replaced by Kongsberg during the spring of 2008. The receiving array is protected by a pure titanium plate. In 2009, a titanium plate was also mounted to protect the SBP120 transmitting array to minimize the use of the plastic windows, which have better acoustic characteristics but are less resistant.

Table 1. EM120, EM122 and SBP120 technical specifications.

| EM120 (1°) | Depth range: 20 to 11000 m Swath width: up to 5 times water depth (ice protection windows reduce this to ca 4 times the water depth) Beam width: 150°x1° Beams: 191 covering a sector up to 150° Frequency: 12 kHz |

|---|---|

| EM122 (1°) | Depth range: 20 to 11000 m Swath width: up to 25% better than EM120 Beam width: 150°x1° Beams: 288 simultaneous beams covering a sector up to 150° Frequency: 12 kHz (chirp mode and dual swath capability) |

| SBP120 (3°) | Frequency range: 3-7 kHz, chirp Vertical resolution: 0.35 ms Horizontal resolution: 3°x3° Integrated with EM120 by using the same receiving transducer array |

| Positioning and motion sensor | Seapath 200 MRU5 (motion reference unit) Heading accuracy: 0.05 RMS (4 m baseline) Roll and pitch accuracy: 0.03 RMS for ±5° amplitude. Heave accuracy: 5 cm or 5% whichever is highest Positioning accuracy: (best case) 0.15 m RMS or 0.4 m (95% CEP) |

Figure 1a. Schematic illustration of the EM120/SBP120 system installed on the Oden. The drawings is a modified version of Kongsberg's original.

Figure 1b. Schematic illustration of the EM122/SBP120 system installed on the Oden. The drawings are modified versions of Kongsberg's original.

Photo 1. Icebreaker Oden placed in dry-dock at Öresundsvarvet in Landskrona. The photo shows the stern of the icebreaker and its two large (4x8 m) rudders.

Photo 2. The constructed steel frame for the combined receiver transducer array (RX-unit) for both EM120 (later EM122 which use the same transducer setup) and SBP120. This frame was mounted in the hull of icebreaker Oden together with one frame for the EM120/122 transmitter and one for the SBP120 transmitter (TX-units).

Photo 3. The first cut in Oden's hull for the installation of the receiving acoustic array (RX-unit).

Photo 4. The first cut in Oden's hull for the installation of the receiving acoustic array (RX-unit).

Photo 5 and 6. (Left) A portion of the SBP120 transmitting array (SBP TX-unit). This 8 m long and 1 meter wide array is mounted along ship. (Right) The 8 m long and 1 m wide EM120 transmitting array, which is mounted next to the SBP transmitting array.

|

|

Photo 7. The 8 m long and 1 m wide receiving array mounted across the ship's hull.

Photo 8. Both the multibeam and subbottom profiler TX-units are covered by ice protection windows made of polyurethane plastic reinforced by imbedded titanium rods. The polyurethane later proved to have been hardened in insufficient conditions resulting in delaminating between the plastic and the titanium. These windows will be replaced by Kongsberg during the spring of 2008. The receiving array is protected by a pure titanium plate.

Photo 9. The transceiver and preamplifier units for EM120 and SBP120. These were installed above the engine room on a specially constructed platform.

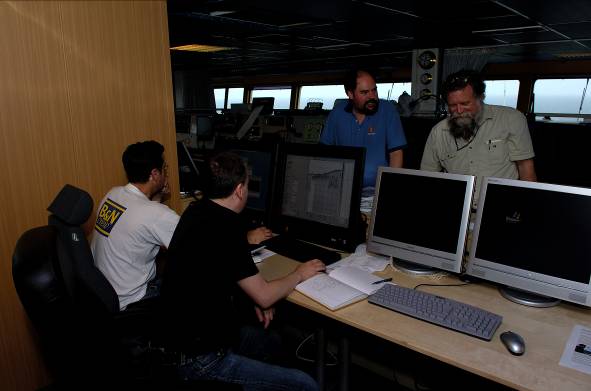

Photo 10 and 11. The multibeam operator station located on the bridge of Oden. This space was specially constructed as an extension of the bridge.

|

|